One of the best welding methods for roll cages is TIG welding. It is the best TIG welder for roll cages, the type of welding that is sanctioned and required for these applications.

The best type of welding for roll cages is TIG welding, according to many experts. In addition, TIG welding is a technique that is done for the safety of roll cages. In this manner, this welding gives a clearer finish to the sheets of metals. For this, many TIG welders are waiting for you, but we suggest you make the right choice.

Here, the best TIG welders for roll cages are reviewed below. Mainly, TIG welders perform more precisely as compared to other welders. In addition, it is a better option for welding chrome. Thereby, read this guide for a better understanding and invest your money in a versatile wedding machine.

Contents

Top 3 best TIG welder for Roll Cages

We have tested several TIG welders for the Roll cage, but only a few are good enough. I reviewed these 3 of the best TIG welders for the roll cage after testing them. Give a read to these welder reviews and pick one for you.

- Power Source: AC OR DC Pulse

- Input Voltage: 110-220V

- Welding material: Aluminum, Steel

- Weight: 90 pounds

- Dimensions: 24 x 19 x 12 inches

- Power Source: DC Inverter

- Input Voltage: 110-220V

- Weight: 22.9 pounds

- Dimensions: 18 x 13.5 x 11 inches

- Input Voltage: 120- 230V

- Weight: 61.6 pounds

- Dimensions: 19 x 10.75 x 14 inches

PRIMEWELD TIG225X 225 Amp IGBT (best AC DC Tig/Stick Welder)

- Perfect for welding several sheets of metals.

- Comes with an HF hand control torch.

- Very versatile.

- An instruction guide is not available.

Are you looking for a welding machine that is suitable for welding roll cages? If yes, then PRIMEWELD TIG225X 225 Amp IGBT AC DC Tig/Stick Welder is the best choice for you. Mainly, this welding machine is very versatile, and you can use it for welding roll cages. However, this welding machine comes with a warranty of almost 3 years.

In addition, this welding machine works at 225 Amps. Besides this, the machine works great during aluminum welding, steel welding, and other thinner sheets of metals. Furthermore, it is designed with the investor’s advanced technology, which makes the machine more beneficial. Above all, the machine supports both the AC and DC inputs and is suitable for industrial use too.

On the contrary, the system of the machine works on both 110 volts to 220-volt power. In this manner, you can use it for completing unlimited welding tasks. Well, the overall weight of this welding machine is about 90 pounds, and the dimensions are 24 × 19 × 12 inches. As the machine uses IGBT technology, then we are sure that the system is very reliable.

Bottom line:

With this welder, you can perform TIG and stick welding without any disruption. You will surely get exceptional welding results from this machine. Thereby, this welder is 100% recommended.

YESWELDER TIG-205 DS HF (Best TIG Welder For Roll Cages)

- Outstanding value considering its price.

- Durable and well-made TIG welder.

- It has dual voltage.

- The lowest setting is 15 amps, which is not good for thin welding sheets.

Chiefly, you can’t go wrong with YESWELDER TIG-205 DS HF TIG/Stick/Arc TIG Welder because all the working features of this welding machine are great. Besides this, this machine is very affordable as compared to other welders on this list. In this manner, this machine performs well for DIY projects or lighter professional projects. Therefore, it is a great choice for newbies.

Chiefly, this welding machine has high-frequency, which makes the overall performance of the machine exceptional. Besides this, this machine has an amperage range of about 15-200 amps. Mainly, the 200 amps range is very good. However, the machine is not suitable for TIG work because most of the thin sheets of metals require an average range of less than 15. But you can’t miss this TIG welder because of its affordable price point.

Due to the price point, it is perfect for those people who want to polish their abilities for welding roll cages. As a beginner, the machine will prove very helpful to you. Here, the complete weight of this welding machine is 13.2 lbs, and the dimensions are 15.7 × 11.8 × 6.3 inches. Lastly, this welding machine is truly versatile, reliable, and portable.

Bottom line:

Here, the best thing about this welding machine is its price point with all the fantastic features. However, there is not any welder that offers you such features with a low price point. So, you must not miss a chance to get this brilliant machine.

Lincoln Electric Power MIG 210 Mp #K3963-1 (best portable and lightweight welder)

- The digital display makes it easy to operate.

- Lightweight and portable.

- Sturdy construction makes the machine durable.

- The power lead is short.

How can we forget about Lincoln Electric Powermig 210 Mp while talking about the best TIG welders for roll cages to buy in 2021? In the competitive market. Undoubtedly, it is a versatile machine because it can perform MIG, TIG, stick, and FCAW welding. In this sense, this machine is multifunctional and easier to operate. In addition, the digital system of the machine gives you easy access to maintain the voltage and frequency during working.

As the machine is easy to use, it is a good choice for beginners. Besides this, all the instructions of the machine are easy to understand. On the contrary, this machine works on dual voltage, and you can easily run the system at 120 to 230 volts. In addition, the machine is capable of cutting thicker sheets of metals without any disruption.

The machine provides a 40% duty cycle at 100 Amps and 25% at 200 Amps. Moreover, the larger color display of the machine allows you to understand the guidelines properly. Here, the total weight of this machine is 61.6 pounds, and the dimensions are 19 × 10.75 × 14 inches.

Bottom line:

Although this welding machine is more expensive, you will never get such fantastic features at a lower price. Moreover, the machine comes with a warranty card. In this sense, there is no point in missing this welding machine.

This article will deal with the best tig welder for roll cages. Often welders are shared between friends or club members, but if you have to buy your own welding equipment I hope the following information helps you find what works best for your needs.

I have been around racing all my life and had many opportunities to learn through welding roll bars for race cars. It can be frustrating to see inexperienced welders botch a good piece of tubing, but the joy you get from seeing your first well-executed fillet is hard to beat.

I have used many different types of welding equipment over the years, both MIG and TIG, but lately, I’ve been pushing TIG welding as my preferred method for fabricating race car parts because it’s precise, fast, and produces quality results that are clean looking with minimal filler material use.

Plus there are no worries about warping parts since you’re only heating the small area being welded rather than an entire sheet of metal like in MIG welding. As far as tig welding goes though…if you want to do it right you need a tig welder that is up to the task. Unfortunately, not all tig welders are created equal and most can’t give you that “Wow” factor when it comes to their performance.

TIG Welding Principles TIG welding requires three separate components for operation: A tig torch, an argon source (gas cylinder), and a tungsten electrode. When the argon gas mixes with hydrogen from the water-cooled tungsten electrode in the presence of an electrical arc it produces a highly exothermic reaction which instantly vaporizes the metal on the surface of both electrodes creating what many consider to be one of nature’s most beautiful sights a plasma flame.

The plasma flame gets hotter than the surface of the sun at around 26,000 degrees Fahrenheit and is hotter than almost any other welding process. The heat quickly melts the electrode which upon striking the weld pool fuses with either parent metal or base metal creating a fillet weld.

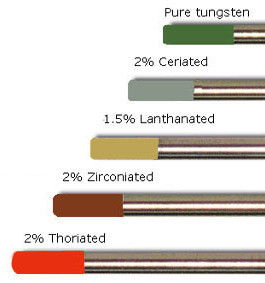

Tungsten Electrodes

The tungsten electrode serves as both the filler material and conductor in TIG welding. You can think of it as a gaslighter on an old Coleman stove that would burn out frequently because it was made from porous materials designed to support combustion rather than being able to hold up under pressure, but no worries…

it’s not nearly as big of a deal when working with less-than-volatile gases like argon. Tungsten electrodes come in various diameters depending on the amperage range they’re designed for, but I typically use 0.023″ to 0.030″ diameter electrodes since my tig welder can handle up to 200 amps of current.

Tungsten Electrode Selection Chart - Welding Tips Blog When selecting a tungsten electrode you must also consider its purity and cleanliness which will affect how smoothly it melts into the weld pool. Dirty electrodes tend to have impurities on their surface that could contaminate your weld, so I purchase only Pure Tungsten brand electrodes from Lincoln Electric because they come pre-cleaned and packaged in a plastic tube that keeps them free from contamination until your first usage.

Argon/CO2 Mix Ratio & Flow Rate

When welding with a “dual-gas” (argon/hydrogen) system, it’s important to make sure the argon purity is high enough and that you’re operating at a pressure and flow rate necessary for proper gas coverage over the weld pool. If you don’t have enough argon in the mix then shielding will be difficult because sometimes all of the argon won’t evaporate before the next arc strike.

If you have too much argon in the mix then shielding will be poor because some of it doesn’t evaporate between strikes leaving a non-transparent film that inhibits your ability to clearly see what you’re welding, but if you have just enough then shielding is adequate and clean up after welding is easier because less flux residue remains on the part.

Frequently Asked Questions

What welder do I need to weld a roll cage?

Most probably, TIG welders are suitable for those who want to weld a roll cage. In addition, for roll caging, try to use materials like metals and chrome.

How many amps do you need to weld a roll cage?

Almost 180-190 amps are required for welding a roll cage. In addition, this amperage range has enough power to tackle such tasks.

Are our roll cages MIG or TIG welded?

Mainly, TOG welds produce better results as compared to MIG welds. In this manner, TIG welding is recommended for roll cages.

Conclusion:

Undoubtedly, TIG welding is more difficult to master as compared to other types of welding. In addition, these best TIG welders for roll cages are also more costly. Anyways, TIG welding is suitable for roll cages. However, we recommend you to buy PRIMEWELD TIG225X 225 Amp IGBT AC DC Tig/Stick Welder as it is perfect overall. In addition, this machine is affordable and versatile.