Check What is a TIG Welder used for? A tig welder is a type of welding equipment that uses a thin metal electrode to heat and melt the base metal being welded. It is used for both high-quality, high-strength joints and thin materials. Tig welding can also be used to join two pieces of sheet steel together without creating a joint in the center. The process involves running an electric current through the torch until it heats up enough to produce molten metal, which is then fed out from the nozzle onto the work surface by compressed air or oxyacetylene gas. In this article, I will be exploring what a tig welder does and how it works!

Contents

FAQS

What is a Tig Welder used for?

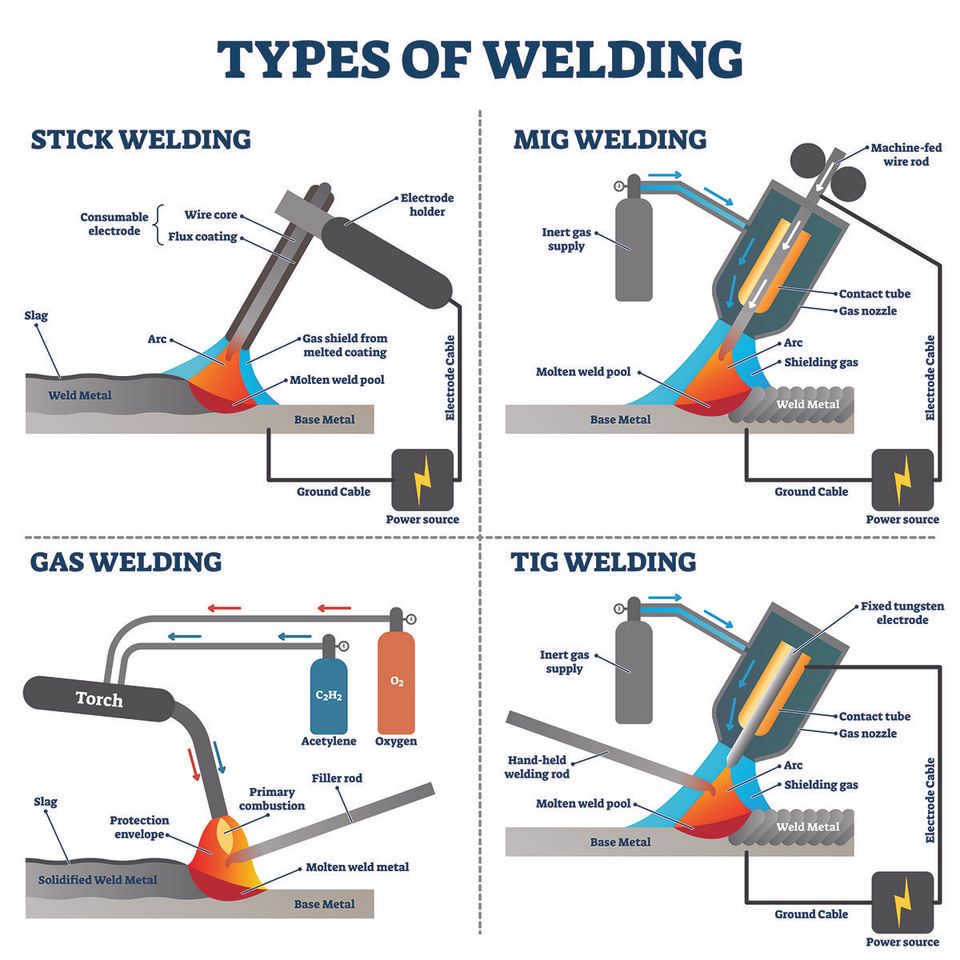

A tig welder is an electric arc welding machine that uses a non-consumable tungsten electrode to produce the weld. Tungsten electrodes are used when welding over 1/16th inch thick metals, whereas mild steel can be welded with direct current (DC) straight polarity without using an electrode at all. The process of gas metal arc welding (GMAW), also known as stick welding, has largely replaced this method in both manual and semi-automatic processes due to its speed and portability. However, for joining heavy sections in fabrication work where high deposition rates are not essential, there is still no better alternative than the versatile AC Tig process. This article will focus on the AC Process in particular.

You may check this also: TIG Welder Inverter Vs Transformer

The Components of the Welding Process

There are three components involved in tig welding; they are the tungsten electrode, argon gas, and the tig welder itself. The tungsten electrode is connected to a constant-current supply (inverter) which provides energy to heat up the tungsten. When the electrode reaches a sufficient temperature it releases electrons into its surroundings creating an electric arc that strikes the workpiece.

The argon gas used during tig welding has many functions. Firstly, it is used to shield the area from oxygen and nitrogen that would otherwise form oxides on metal surfaces when heated at high temperatures. Argon also helps transfer heat away from the tip of the torch making sure that all of it goes towards heating up your workpiece. Finally, it is used to shield the arc itself making sure that all of its energy gets transferred into your workpiece. Because argon is inert, it doesn’t react with other substances and so will not contaminate or distort the weld pool.

How to Weld with a Tig Welder

Types of Welds that you can create with a Tig Welder

There are three basic types of welds that you can perform with a tig welder: fillet, groove, and horizontal. Each requires different joints and techniques to achieve the best results.

Fillet Welds produce a smooth transition from one metal surface to another when using round pieces of material such as tubing or bar stock. This type of weld is the most commonly used since it provides high quality in relatively low time and cost. It produces less heat than other forums so it’s ideal for thinner materials where distorting the shape would be more obvious. The bead size produced by this technique is usually 1″ in diameter or smaller depending on your amperage setting and material thickness.

Gro welds are used for joining pieces of material that are flat or close to being flat, it can be done on either side of the joint. The most common types of welding used with this technique are fillet and plug welding.

Horizontal Welds are needed for materials that are not round in cross-section such as square tubing or sheet metal. For efficient use of the tungsten electrode, you will need to keep it perpendicular to the centerline or plane of the part being welded so you may need to rotate your pieces accordingly. It is also possible to create a slightly angled weld by angling your torch toward one end while keeping it at a right angle from the table’s surface (the “chin up” method). This type of weld is similar to coping since it requires more vision than other types.

Safety Precautions when using a Tig Welder

When using a tig welder there are some important precautions to take into account.

First, you must ensure that the electricity in your shop is shut off before starting up any welding equipment. This includes all other types of welders not just your Tig machine.

Always use welding gloves, boots, and other PPE when working with any type of welding equipment or materials since it can be very hot or hazardous to your health if proper precautions are not taken.

Before starting any welding project, read and fully understand all of the instructions that came with your equipment. Make sure you know how to properly clean and store it once your project is complete. Also, keep in mind that even experienced welders can have a “bad day”. Be aware of the dangers involved with the materials you are using, as well as other physical factors that can affect your senses.

Tungsten electrodes are very brittle and will break if they are bent, stepped on, or maybe damaged by your welder. If the tip of your electrode breaks it may fall into your machine and become jammed in the collet, hose, or nozzle. This is why you should always use a cup brush to clean the inside of these areas after each use.

Final Words

A Tig welder is more than just a machine, it’s also an investment in your future. This information has shown you some of the things to keep in mind when choosing tungstens and what type of tig welding projects are best suited for each electrode size. With enough practice, any standard tig welder can be used to create beautiful welds.