The purpose of this article is to give an in-depth analysis of these giants called Eastwood vs Miller that dominates the TIG welder industry.

In addition to several TIG welders, Eastwood is renowned for manufacturing welding machines in general. Compared to TIG welders from different brands, they are significantly less expensive. TIG welders from Eastwood are capable of exchanging in a split second, working in almost any electricity setting, and producing quality welds regardless of metal making it the best tig welder for the money.

On the contrary, miller welders can be the best choice when it comes to TIG welders since they are known to be durable and reliable. The Miller Electric Company has been creating welding tools since 1928. A key aspect of their operation is the precision of the arc and the cleanliness of the welds.

Contents

FAQS

Eastwood Vs Miller TIG Welder - Are They Worth the Money?

In terms of fine details and precision, TIG welding produces the best results. Despite their complex operation, these welders produce the best-looking arcs. TIG welding can be challenging as well as enjoyable if you have the right machine.

We will compare and analyze the TIG welding machines manufactured by Eastwood and Miller in detail. You will see the differences between their performance, prices, and features in the following steps.

So let’s get busy.

1. Controls Both Thin and Thick Metals

As a welder, it’s important to have a welding machine that is capable of handling a wide variety of metal types. The good news is that TIG models from Eastwood have the ability to weld both thin and thick metals perfectly. The Eastwood 12746 skilfully welds aluminum and steel and stainless steel. On 220 VAC, it is capable of welding 1/ 4 “ thick metal with more precision.

Whereas Miller TIG models are also versatile and offer the welding of both thin and thick metal and give you a better welding experience. Miller Syncrowave 210 is excellent to handle thin metals during welding tasks. With 5 amps of power, it welds thinner materials than other machines in its class. Similarly, the Miller Diversion 180 offers welding jobs with a maximum thickness of 3/ 16” thick metals. A machine like this is superior for smooth arcs when you are welding aluminum.

2. Voltage Control

It is amazing to know that both Eastwood and Miller come with the capability of operating on dual voltages such as 220 Volt and 120 Volt depending on your power requirements and welding task.

With the Eastwood TIG 200 AC/ DC, you don’t have to worry about voltage. It can be operated with 110-120 VAC, 50/60 Hz., or 220-240 VAC, 50/60 Hz. Keeping in mind the potential impacts of voltage fluctuations, Eastwood recommends at least a properly grounded 110-120 VAC 50/60Hz., 20 Amp circuit or 220-240 VAC 50/60Hz., 30 Amp circuit.

A machine’s output will depend on the materials it has to weld, whether that is AC or DC. The Miller Diversion 180 operates between 120 volt and 240 volts. Additionally, with the multi voltage plug (MVP) from Miller, it can be directly connected to 115/230 Volt outlets without tools and it does not sacrifice its performance.

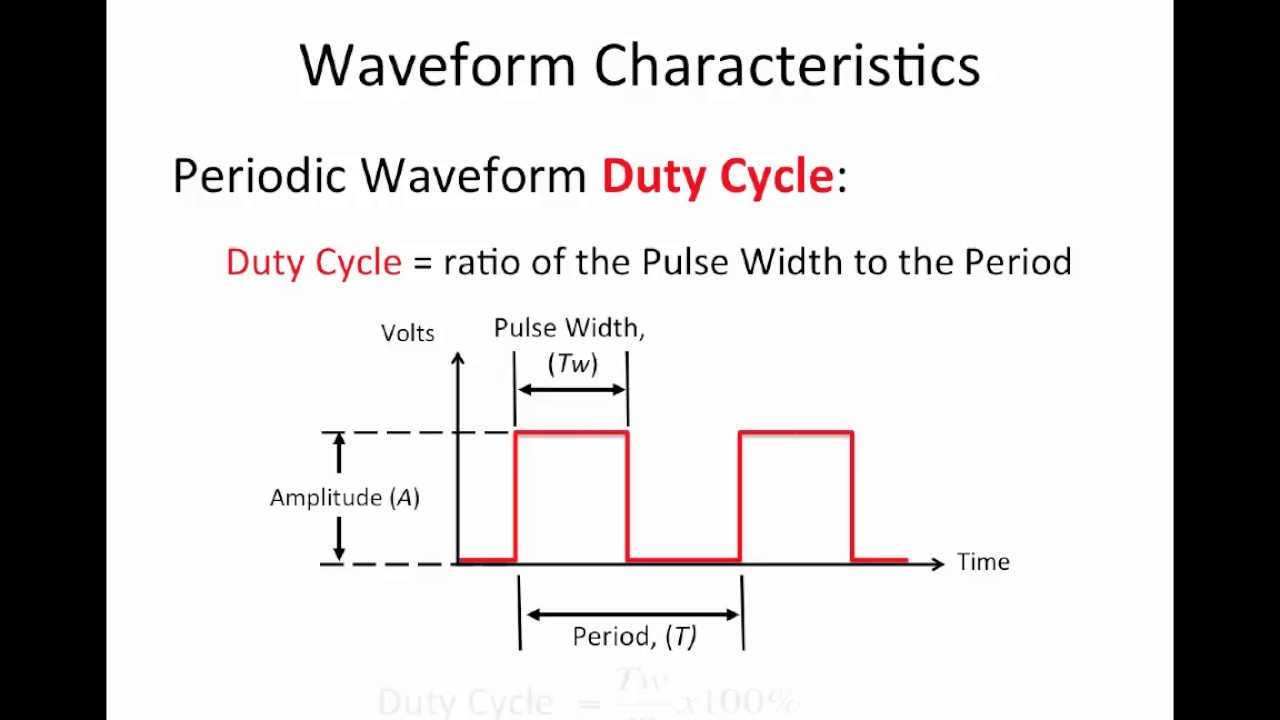

3. Duty Cycle

Depending on the amperage, the duty cycle changes. When the machine produces more amps, it will heat up more quickly, which will result in a reduced duty cycle. Duty cycles will increase as amperages decrease.

If we talk about the duty cycle of Eastwood welding machines, it varies from model to model. It can offer 60% duty cycle at 145 amps where the voltage is 120. If VAC increases to 220 the output rate is 60% at 190 amps.

Comparatively, the Miller Diversion 180 offers a 35% duty cycle with rated output [email protected] V. Moreover, the Miller Dynasty with the rated output 150 A 16 V offers a 60 % duty cycle. So choose the model with the best duty cycle to make welding a great experience.

4. Design And Features

Like ahp vs Eastwood tig welders, these brands also have some common features. If we compare the features of both welding brands, Eastwood and Miller, both have different features. But Miller has more complex operations as compared to Eastwood. In terms of similarities, both have HF start and foot pedal control ensures convenience during welding projects. Coupled with this, both are lightweight and have built-in handles to make the best portable tig welders.

In terms of differences, it’s so easy to operate the Eastwood function meanwhile the Miller has complex functions and takes time to understand.

5 . Prices And Warranty

As far as the prices are concerned of both TIG welding machines, the Eastwood tig welder has the upper hand due to its economic prices. So it is the best choice for those who are enthusiastic about TIG learning in their leisure time or for those who need it to do minor home tasks. The price ranges from $400 to $1200.

On the flip side, the Miller is quite expensive and the price ranges from $1800 to $10,000 making them the most expensive TIG welding machines. But the extended precision and quality welds justify the price.

If we talk about the warranty, it is always wise to consider it to make your purchase a long-run investment. Eastwood offers 1 to 3-year guarantees on different models with a 90-day money-back guarantee. Conversely, Miller also provides a return and repair guarantee within 3 years.

Conclusion

Both Everlast and Miller have their own pros and cons making them different from each other. Miller is highly suitable for professional and serious welding projects but its high price tag does not make it affordable for everyone.

In the same fashion, the Eastwood is cost-effective but its limited functions do not allow it to do all types of welding projects. Read more