Here we are explaining MIG or TIG welder for beginner. Whenever we talk about welding metal or alloys together, the primary machines mentioned are MIG or Metal inert gas and TIG or Tungsten inert gas. Each welding machine has its own characteristics when it comes to different materials and thicknesses. In short, your requirements and project will lead you to understand what exactly you need, MIG or TIG.

For beginners, understanding the nature of the material can be challenging, and then deciding on the welding machine is an entirely different process. Therefore, we have gathered some basic information, their uses, and many other factors that every welder should know before answering the question; MIG or TIG welder for the beginner.

Contents

The main difference: MIG vs TIG Welding

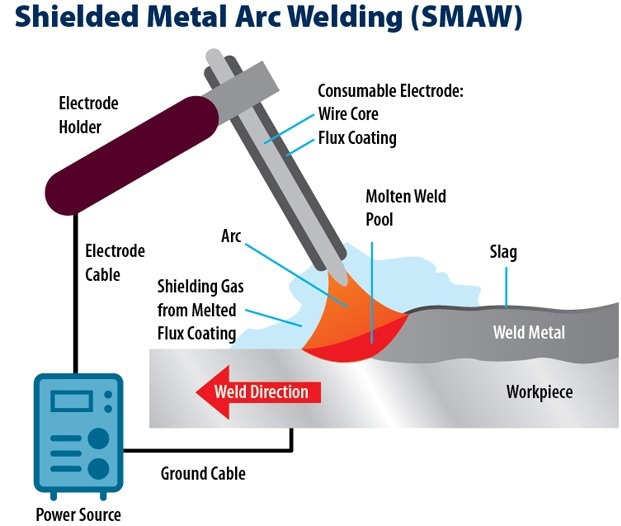

Let us first discuss the construction and mechanism of both welding machines. The sole purpose of MIG and TIG is to produce a solid electric arc during the welding. The welding is where the material melts with the filler material to fill in the gap between the two metals. This helps in creating a solid bond between the metal plates, sheets, and even rods.

TIG and MIG both work on the same process with metal and the electrode. Both machines process enough temperature in the electric arc to start the metal and start welding.

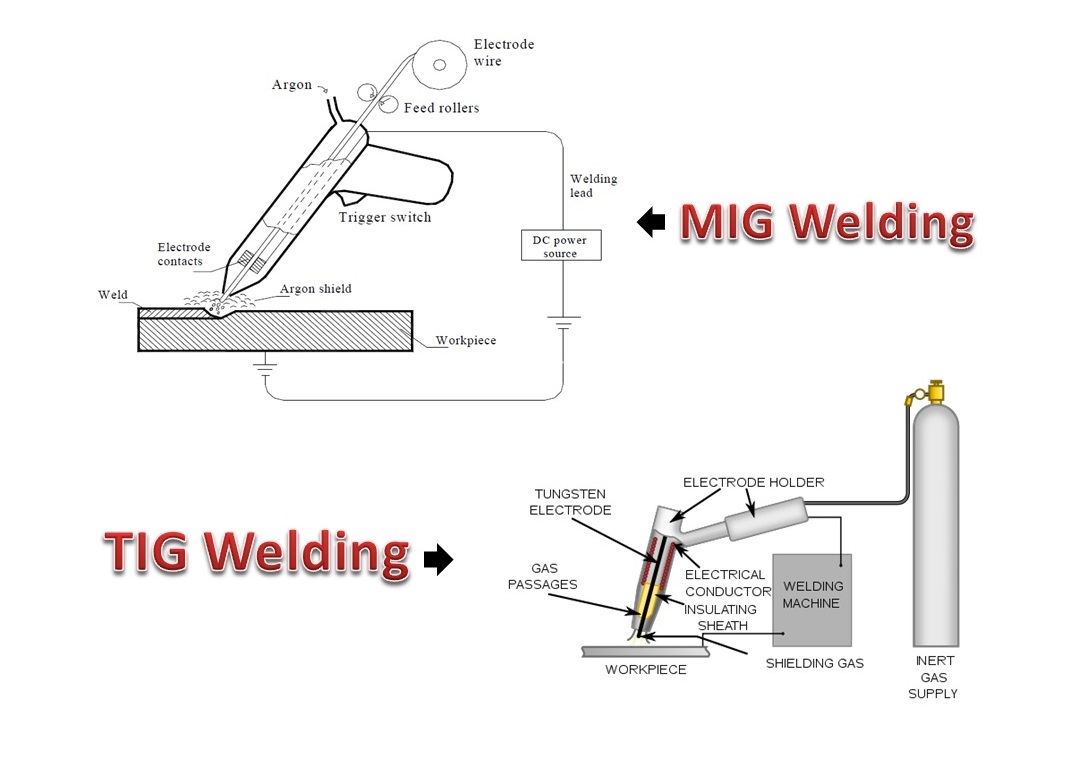

Now, what features make them different? TIG has a tungsten electrode that conducts the current through the subject metals. It is the internal mechanism to produce the heat in the electrode. The heating from the electrode melts the metal and the external filler into a puddle. This puddle then fills in the gap between the metals, hence joining them together.

While in MIG, the filler material is feeding the electrode when heating up. No external filler is involved in the entire process, so using just one hand for the welding. Moreover, the gas is introduced to the process when the filler and metal are melted into the puddle to protect it.

This is also the reason that welding from MIG is so quick and gained popularity over TIG. If you ask experienced welding about the best type of welder for beginners, they will answer the MIG welder. MIG is easier to learn and has a variety of techniques as well. But if you want to have a cleaner finish and good control, you can use TIG.

TIG Welding Methods and Uses

TIG welding works on both AC and DC power supply with external control of the gas that the user controls all the time during welding. For TIG welding, there is only one technique for welding, the Push or Drag process. This technique requires a good hand to hold the arc or pin and another hand to hold the filler. Then you slowly push the arc into the metal and the filler to weld.

TIG welding is all about clean welding and good eye-to-hand coordination. Honestly, if you have a good practice, you will notice how good the wok angles are. But do consider the welding area. TIG is the perfect choice for the thinner metals that need short runs; otherwise, if you are using it for long welding runs, the deposit rate is slow and gets expensive with the filler cost.

MIG or TIG welder for beginner

Advantages of TIG welding

Disadvantages of TIG welding

MIG welding Methods and Uses

The MIG welding machine has a constant voltage DC power supply. The wire-feed system used in the MIG welding machine can use three types of attachments, Push-pull and pinch roll, and spool gun.

The gas protects the welding arc while the wire transfers the current in the arc. MIG further have types of torches, air-cooled torch, and water-cooled torch. For lighter welding projects, air-cooled torches are recommended and for the thickness ones, the water-cooled torch.

MIG welding can be used with two welding techniques, pull and push. The push techniques work the same as in the TIG welder, but the pull technique requires the user to pull the puddle towards the user while sealing the joints. The most recommended welding technique for MIG is pull because it is more durable and easier to see while working. Whereas the push may be harder to see, and hand angles can be so tricky.

Furthermore, the MIG is perfect for thicker metals that need long runs. Another important thing that made MIG preferable is the deposit rate. It is much higher than TIG; in short, the work is done quicker than you expected. Therefore, MIG welder for beginners by the experts.

You can also read Spool Gun or Tig Welder to know the differences between the two.

Advantages of MIG welding

Disadvantages of TIG welding

Final Verdict

When Both TIG and MIG have their benefits and drawbacks when it comes to MIG or TIG for beginners. But one thing we can conclude is that TIG or MIG welding machines entirely depend on the nature of the project. We recommend that if your project uses thin to medium thickness and needs durability and precision, then feel free to use TIG.

But if you are looking for heavy-duty welding and have some extra cash in hand, go for the MIG welding machine. Honestly, it has so many attachment options, and you can try the pull and push technique according to the project. In short, the possibilities are endless.